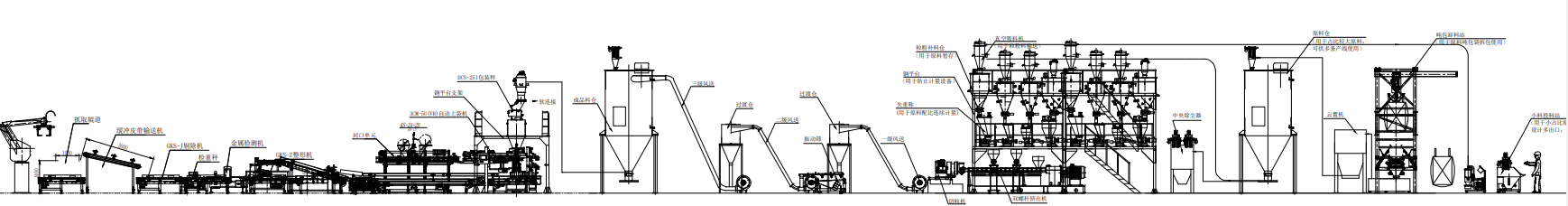

NPCMP-S fully automatic modified pre dispersed masterbatch production line

1. Based on the processing scenario of nano high concentration functional masterbatch. Masterbatch is a mixture composed of carrier material and ultrafine powder, with the carrier material accounting for 10-15% and the filling functional material accounting for 85-90%.

2. Solve the problems of material bridging, difficult feeding, powder emission, low output (72 type 44:1 extruder, 450Kg/H), and severe temperature accumulation in the current production state.

3. Equipped with powder arch breaking and anti bridging, optimized feeding design for exhaust without material emission, good sealing without powder emission, and able to smoothly feed materials weighing over 700Kg/hour. The feeding device is installed above and on the side of the extruder, and is closely connected to the batch scale; The extrusion equipment has precise temperature control and reasonable design for the processing of powder materials and thermosensitive materials, achieving a fully mild plasticizing effect.

4. The equipment unit includes a central silo unit, a metering and mixing unit, a mixing modification unit, an extrusion host unit, a cutting unit, a weighing and packaging unit, an automatic palletizing unit, and an environmental protection treatment unit.