summary

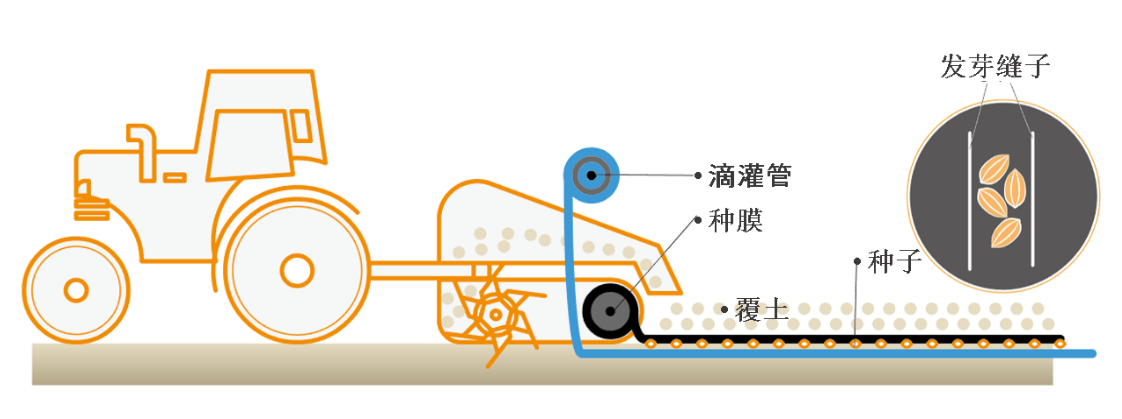

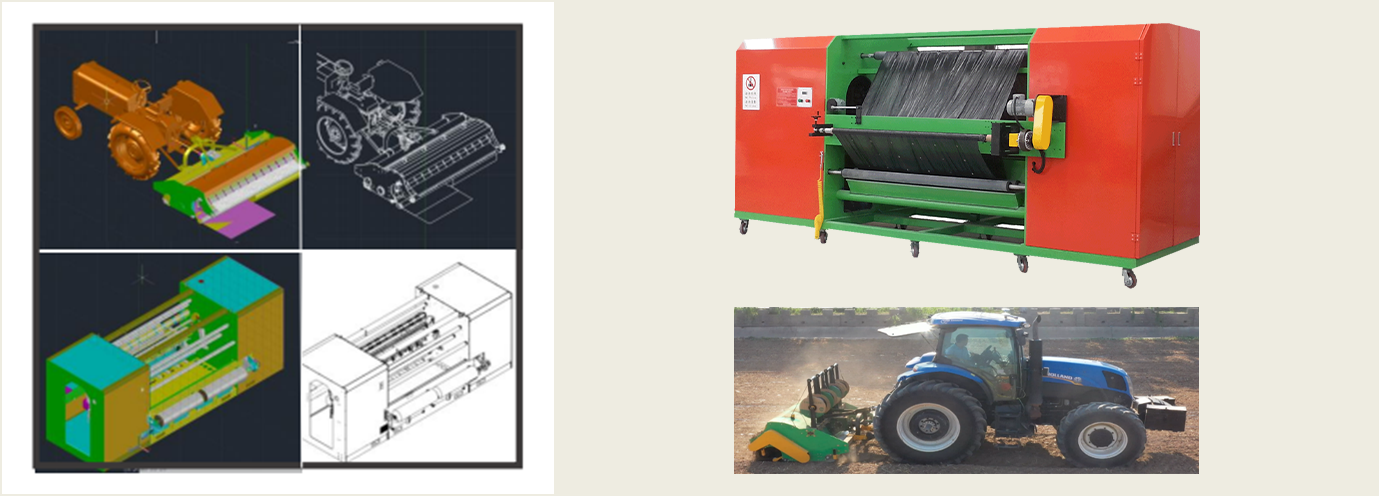

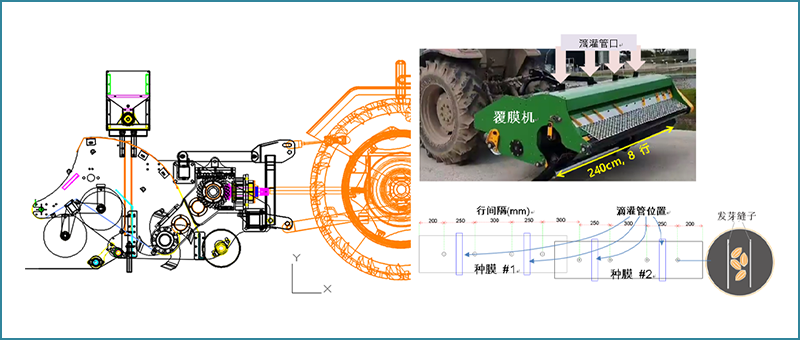

Using automated machinery, seeds and fertilizers are glued onto biodegradable films, and specialized film covering machines are used for laying and sowing, while fertilizing and laying drip irrigation belts. Efficient and automated planting efficiency reduces the labor of seedling transplanting and weed control, while biofilm inhibits evaporation and avoids significant water resource waste. Due to the heating/moisturizing effect of biofilm, the yield is increased by 15-20%. Reduce carbon emissions. This technology originated from South Korea and has been tested and validated in regions such as Japan, the United States, and Vietnam.

1. Establish a demonstration center in units of 2000 hectares and carry out scale replication and promotion. The investment for building a demonstration center is about 1.5-2 million yuan.

2. Main business: Providing production of adhesive agricultural film, offering mulching planting, selling mulching machines, selling agricultural materials, and providing planting services. Sales revenue of 20 million yuan/year, profit of 2.5-3 million yuan/year (including film, seed, fertilizer, drip irrigation pipe trade)

Efficient and automated tasks that save manpower

1. Prefabricated heavy film:Fertilizer and seeds evenly and automatically adhere to the film, with a pre made seed film operation of 15 acres per hour;

2. Efficient film covering:完成100亩播种需3小时,无需移栽、除草,高效省力。

1. Water saving benefits:Compared with traditional flood irrigation, it can save about 65% water, automatically irrigate, control time and water volume, and maximize water and fertilizer savings;

2. Reduce carbon emissions:Covering with biodegradable plastic film can significantly reduce the emissions of carbon containing gases such as CH4 and CO2, with a reduction rate of about 40-60%;

3. Economic benefits:An increase of 15-20% in yield and a net profit of 550-600 yuan per mu; The one-time investment cost of plastic film and drip irrigation can be fully offset by items 1-3, as shown in Table 5

Conclusion: Compared with traditional cotton planting, it reduces farmers' planting costs by about 275 yuan/mu, which is 18% lower.

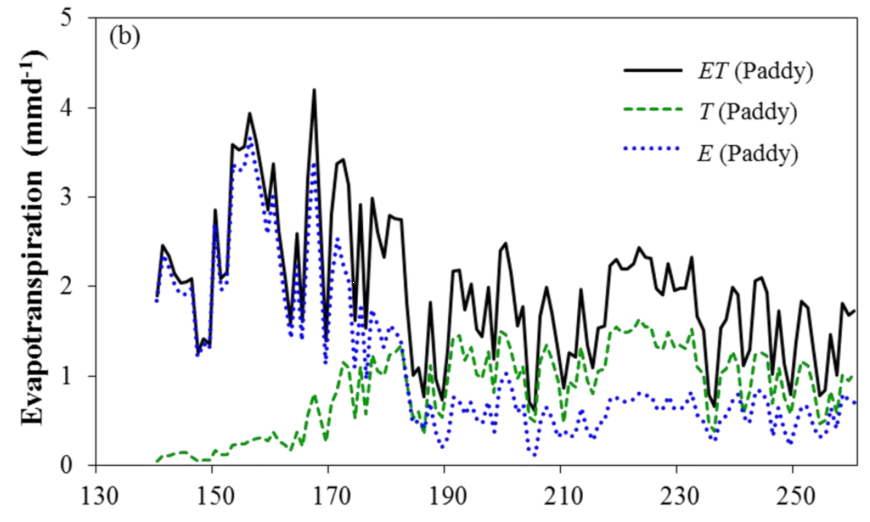

Figure V-2 Daily evapotranspiration (black line), canopy transpiration (green dashed line) and evaporation (blue dotted line) of paddy rice (b). (n=3, +/-SD)

Through analysis of water use efficiency

Compared with traditional flooded rice cultivation, reducing farmers' planting costs by about 2500 cubic meters of water per hectare